LIQUID METAL FURNACES

Advanced solutions, drawing on decades of experience

About Our Liquid Metal Furnaces

Gautschi has over 100 years of experience in the design of melting and holding furnaces for the aluminum industry.

We are known for the robust construction of our products, modern and innovative technologies and quality service. Furthermore, we are represented throughout the world by more than 500 furnaces, ranging from 10 t to 170 t liquid metal capacity.

Round, Top-Charged Melting Furnaces

Up to 170 t metal capacity – melting rates up to 45 t/h

- Stationary or tilting type

- Cooled furnace cover structure

- Dry cleaning door frame design

- Melting rates up to 45 t/h

- Long service life & high reliability

- High efficiency and low emissions with our new generation of regenerative burners: VAREGAENVICOM®

Rectangular and Oval Melting and Holding Furnaces

Up to 165 t metal capacity

- Fixed hearth or tilting type

- Single or multiple doors, available over the full furnace width

- High efficiency and low emissions with our new generation of regenerative burners: VAREGAENVICOM®

Gautschi Burner Systems

1000 kW to 11 000 kW

- Cold air

- Regenerative VAREGAENVICOM®

- For NG

- Energy efficient

- Fulfill all new environmental requirements, however stringent

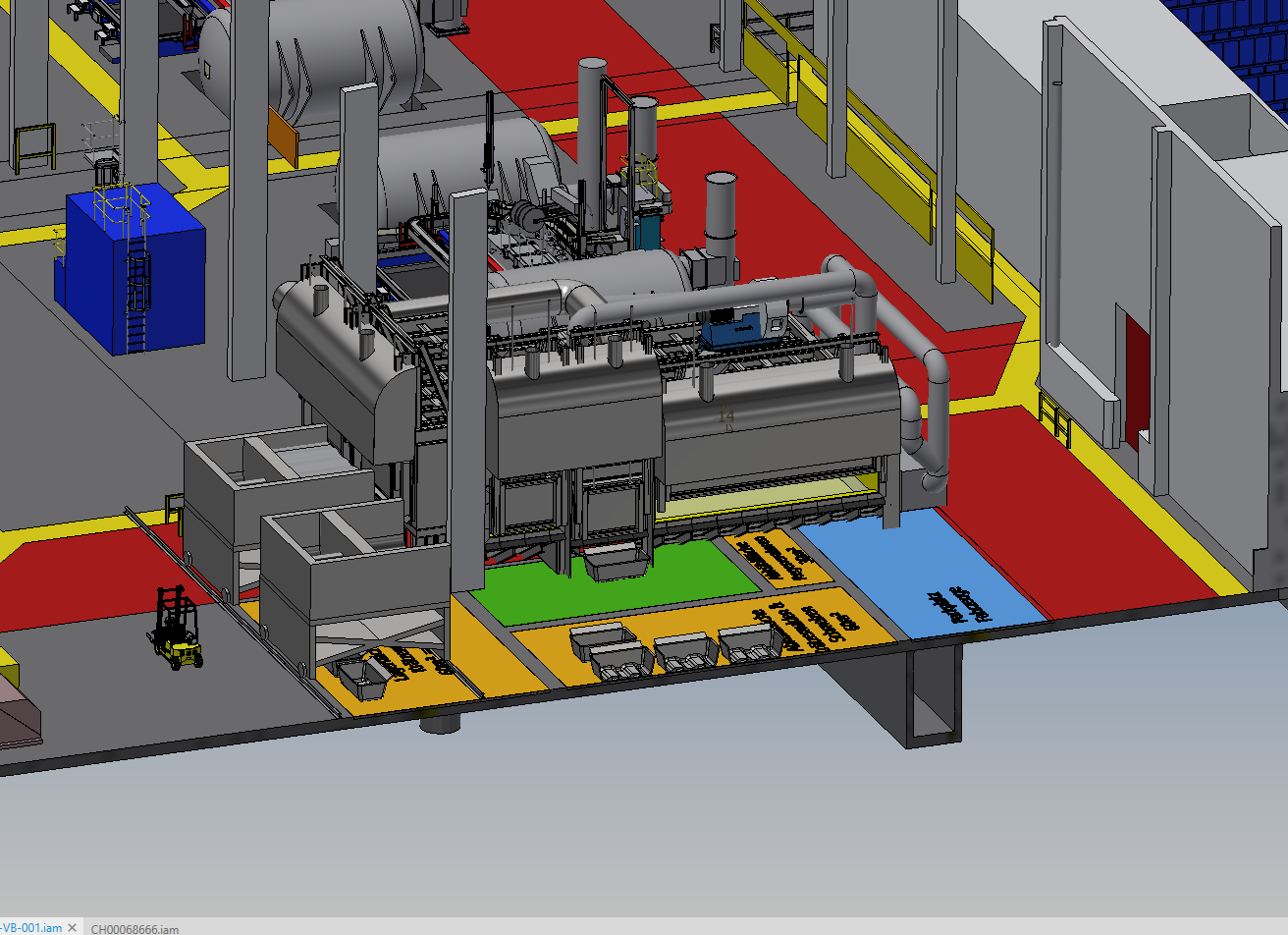

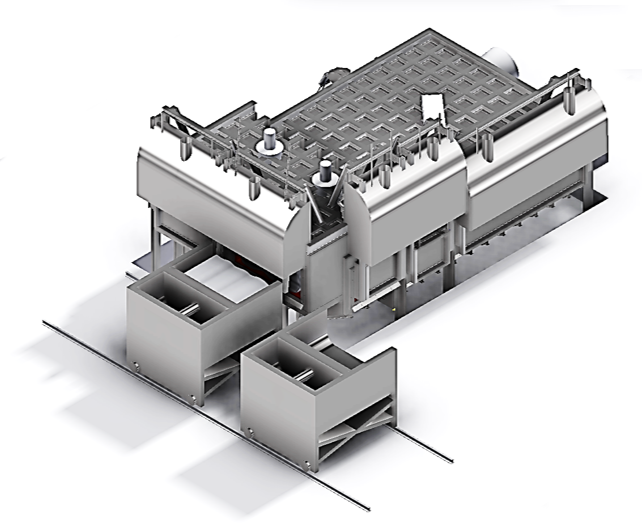

Multi-Chamber Furnace

- Bath volumes from 15 t up to 140 t

- Melting capacity: up to 15 t/h, continuous

- EMS stirrer for liquid metal circulation throughout all furnace chambers:

- Reduced dross

- Increased output

- Suitable for both continous chip and shredded scrap feeding

- Reduced maintenance and higher availability, compared to a pump

- Extremely low fuel consumption, achieved by using both regenerative burners and the pyrolysis gas generated by preheating the scrap

Hybrid Rotary Tilting Furnace

- Scrap remelting and dross recycling

- Several HTRF installations worldwide, profound process

know-how - Charged Material:

- Dross

- Scrap

- Chips

- Standard sizes from 4 to 25 t capacity (50 t is under development)

- 1 TR2

- 2TR5

- 3TR9

- 4TR12

- (5TR25)