COMPLETE CASTHOUSES

Complete Casthouses

As a member of the EBNER GROUP, Gautschi is the market-leading expert in the field of liquid metal furnaces. The companies that form the EBNER GROUP value each other’s expertise and mutually support one another. This allows Gautschi to benefit from synergies that add value and promote the market presence of the EBNER GROUP as a whole: the full solution provider.

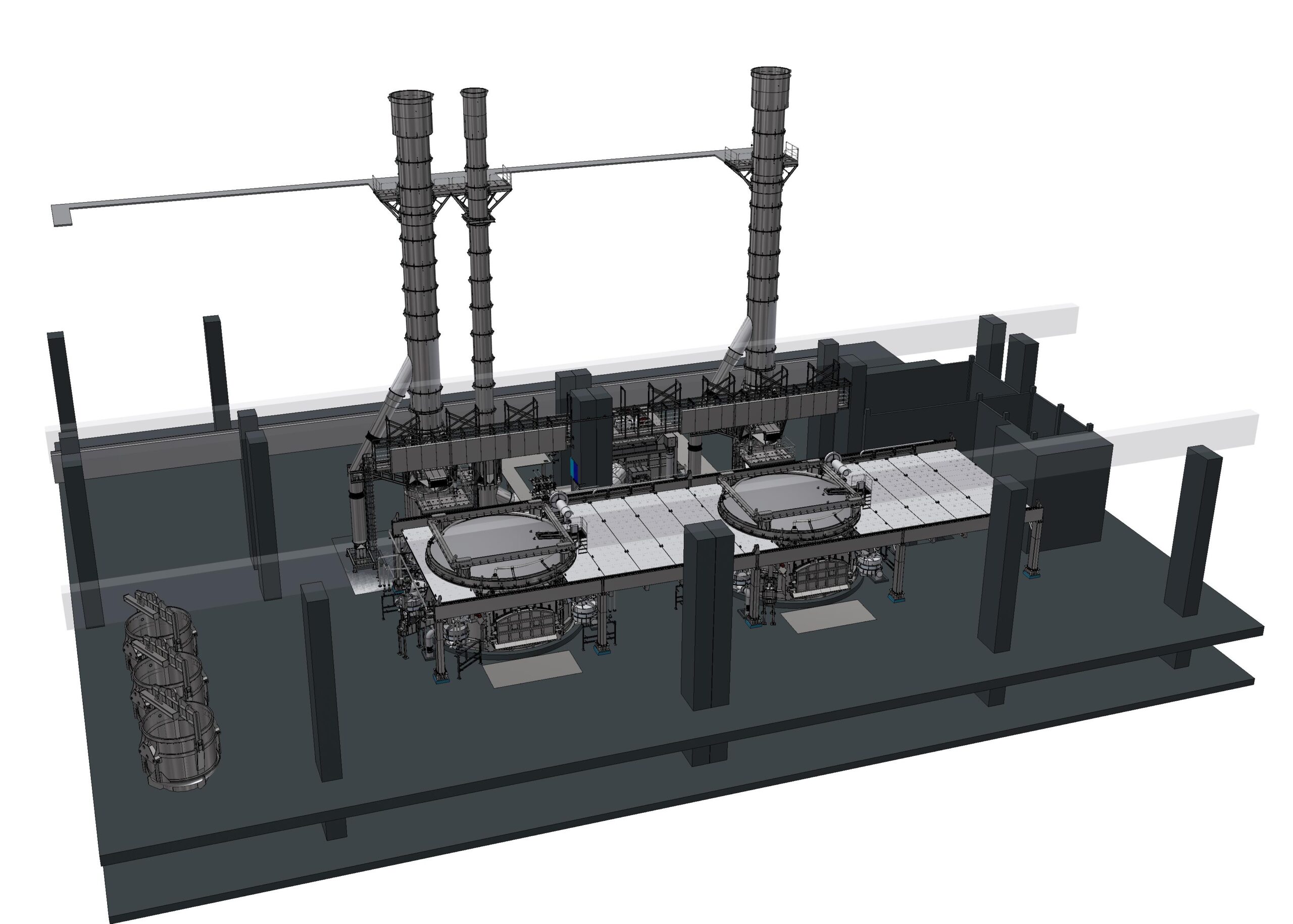

Typical plant layout

Remelt Plant

- From in-house rolling mill scrap to new rolling ingots

- Includes:

- 2x Stationary Round Top Charged Melting Furnaces 115 t

- 1x Rectangular Tilting Holding Furnace 105 t

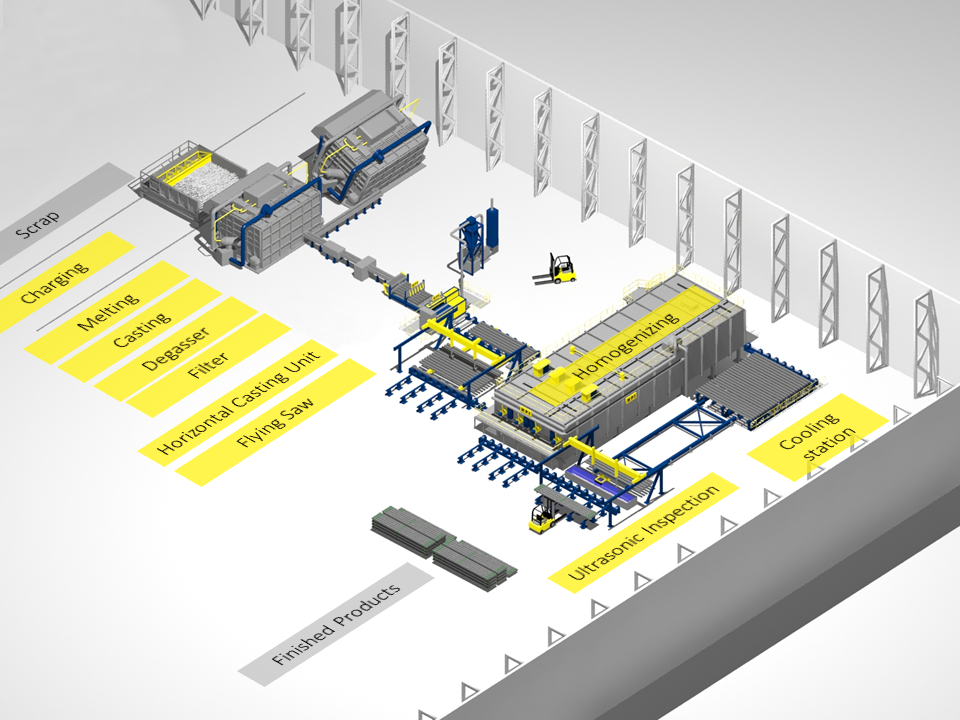

Typical plant layout

Aluminum "Flex" Remelt Plant

- From scrap to ultrasonic-tested billets in a continuous production line.

- Includes:

- HPI Charging Machine

- 2x Gautschi SWVE

- HPI Launder System incl. Filter and Degasser

- HPI Horizontal Casting Facility

- HPI Continuous Homogenizing Furnace

- HPI Automatic Sawing and Packing Equipment

- Only 2 operators per shift

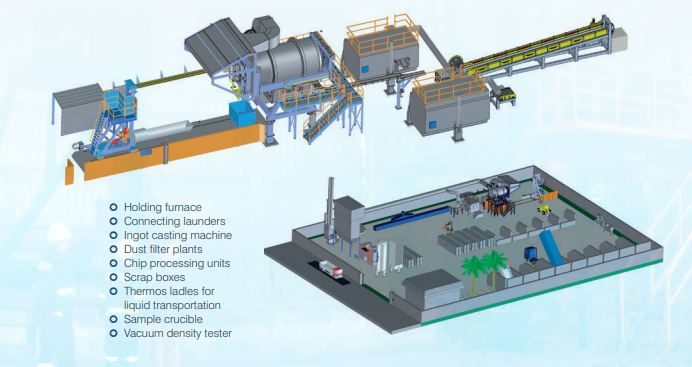

Typical plant layout

Aluminum Scrap and Dross Remelt Plant

- From scrap to foundry alloy ingots

- Includes:

- Charging Machine

- MASTERmax HRT Furnace

- Transfer Launders

- Gautschi WVE furnaces

- HPI Horizontal Casting Plant for ingots

- HPI Automatic Stacking and Packing equipment

- Only 2 operators per shift

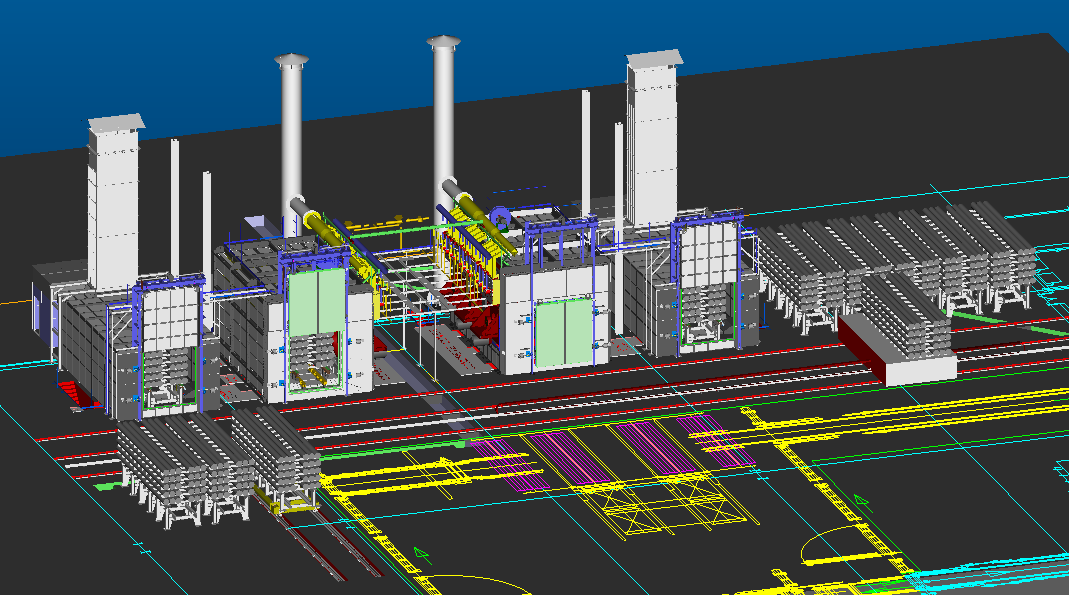

Typical plant layout

Billet Heat Treatment Plant

- Fully automated heat treatment processing of extrusion billets

- Includes:

- 2x Batch Homogenizing Furnaces – 60t

- 2x Cooling Chambers

- 1x Charging Machine – 75t